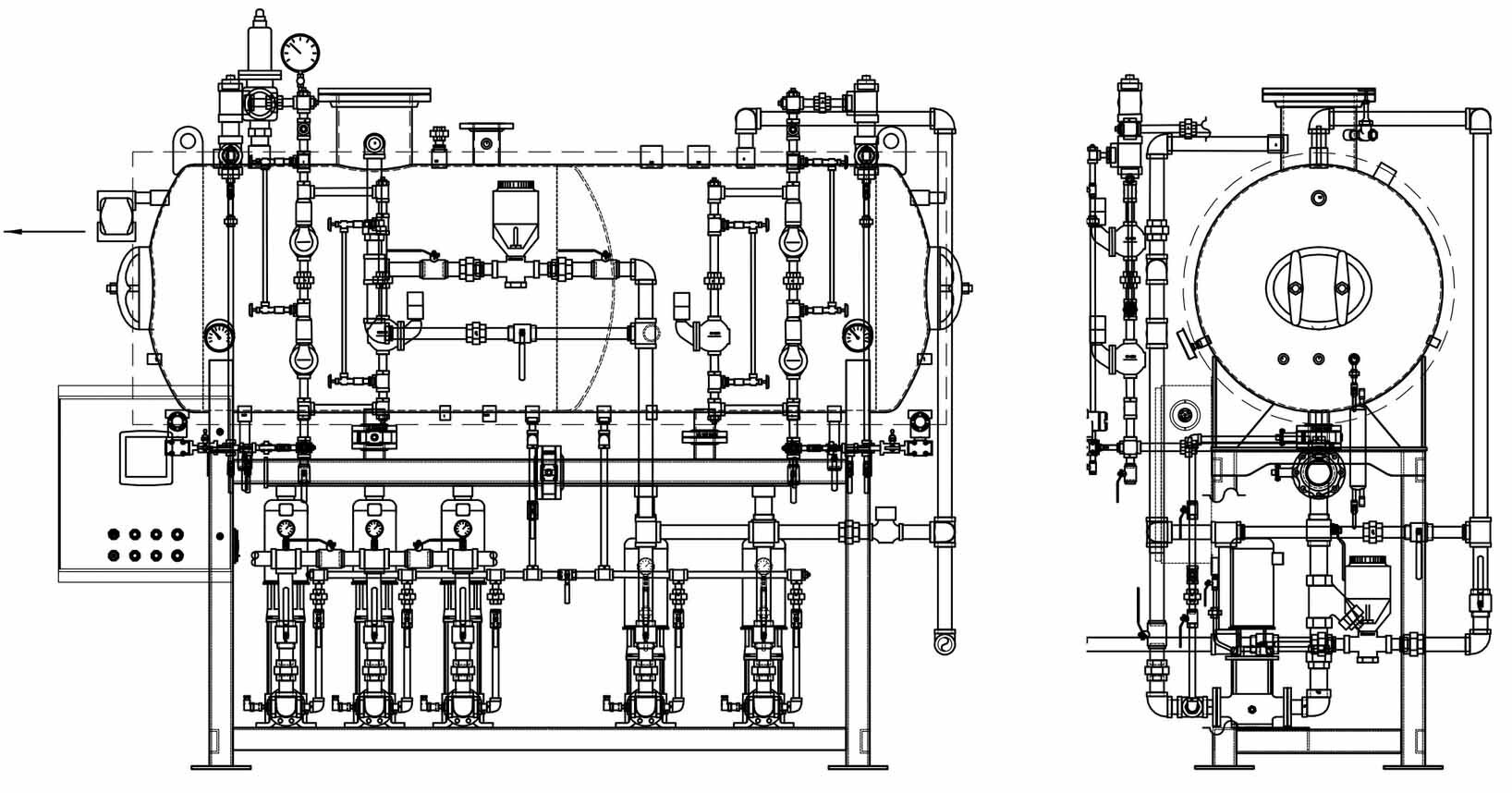

The Hurst Dual-Tank Oxy-Miser “DOM” series boiler feed system is a spray-type Deaerator and condensate surge tank packaged together as a single unit sharing a common stand and pump header.

All Deaerators are ASME Section VIII unfired pressure vessels, which must be taken offline from time to time for inspection & maintenance as required by jurisdictional authorities and/or insurance providers. The Hurst DOM DA/ST combo tank is available with emergency cross-over piping which allows the surge tank to act as a temporary boiler feed system, keeping the boiler plant in operation while the DA is out of service.

Changing between the two tanks is a simple procedure. First, the DA is isolated from the boiler feed pump header by closing the butterfly valve located between the outlet flange of the DA and the boiler feed pump header. A second isolation valve in the pump header is then opened, allowing the boiler feed pumps to pull directly from the surge tank. Pump recirculation lines are re-routed to the surge tank with ball valves included with the factory piping. Once the Deaerator has been returned to service, the above steps are followed in reverse order, and the DOM tank is back in normal operating mode within a matter of seconds.

Why Deaerate?

The use of deaerators has long been used in power plants and water tube-type boilers, primarily because they remove undissolved oxygen and raise the temperature of the feedwater. These advantages are important today

for firetube boilers as well, due to higher capital investments. Operating costs can be reduced by recovering flash steam when returned by high-temperature condensate. This feature also raises the feedwater temperature, thus requiring less boiler fuel to convert the feedwater to usable steam.

Boiler tubes, condensate lines, and process piping have a much longer useful life by eliminating the pitting action of untreated water. This advantage alone justifies the cost of a DOM Series deaerator.

How Does it Work?

Fresh make-up water is fed into the deaerator through the inlet water connection. This water passes through the steam-filled heating and venting section. The water temperature is raised, and many of the undissolved gases are released. As the water passes through the assembly, it flows to a scrubber section where final deaeration is accomplished by scrubbing the water with oxygen-free steam. This steam is induced through a stainless steel spray valve assembly which causes the high-velocity steam to break the water down to a fine mist through a violent scrubbing action. The deaerated water spills over to the tank's storage compartment for use by the boiler, and the gases are vented to the atmosphere.

The Hurst Dual-Tank Oxymiser deaerating boiler feedwater system eliminates the need of expensive oxygen scavenger chemicals and also offers the following advantages:

- Removes carbon dioxide as well as oxygen.

- Raises the boiler feedwater temperature, eliminating thermal shock in boilers.

- Improves overall boiler room efficiency.

- Feedwater pumps are sized for each individual application assuring total compatibility and optimum operation.

- Vessels are ASME Code constructed for 50 psig.

- Compact design means smaller boiler room requirements.

Standard Equipment

- Welded steel tank, designed for 50 psig as per the requirements of ASME Code deaerating section with spray valve.

- Structural steel stand with square tubing and steel pump platform.

- Feedwater pump and motor sets, sized for each application.

- Water inlet valve assembly for condensate return and fresh water.

- Overflow trap, tank thermometer, pressure gauge.

- Steam pressure reducing valve assembly with temperature controller.

- Safety relief valve(s), vent valves, tank drain valve.

- Water gauge glass set with cocks, drain valve, and protection rods.

- Pump suction piping with strainer and shut-off valve.

- Integrated Control Panel