Hurst Boiler | March 5, 2024

Hurst Boiler | March 5, 2024

Hurst Boiler | March 5, 2024

Hurst Boiler | January 21, 2024

Hurst Boiler | October 26, 2023

Hurst Boiler | June 15, 2023

Hurst Boiler | April 24, 2023

Hurst Boiler | July 30, 2022

Casa Herradura has become a model in advancing clean energy manufacturing to ensure that the agave bagasse and process waste material generated during the agriculture and production process is separated, utilized, and recycled. Hurst Boiler helped Herradura obtain fuel savings of up to 70% by switching to biogas/biomass fuels and has met its projected ROI of 13 MONTHS.

Process Heating & Cooling | July 13, 2022

The Hurst internal stack economizer is a factory-optional device that is designed to increase the operating efficiency of a boiler, cutting down on its operational costs over the lifetime of the boiler.

Hurst Boiler | January 21, 2022

Hurst Boiler is proud to introduce the completely new and innovative Hurst EGO Series 3-Fuel Boiler. These EGO Series Boilers can be fired with any of three different fuels - gas, oil, or electricity.

Hurst Boiler | June 4, 2021

georgia.org | March 4, 2021

A tequila plant in Mexico. A COVID-19 hospital in Saudi Arabia. A turkey farm in North Carolina. A brewing company in Africa. These are just a few of the diverse operations powered by customized boilers made by Georgia-based Hurst Boiler & Welding.

georgia.org | March 4, 2021

A Q&A interview with Kelly Griffin, Legal Support Specialist

Hurst Boiler | January 5, 2021

Hurst Boiler | October 29, 2020

Hurst Boiler shares details on reaping the rewards of biomass energy and its success with a poultry manure-to-energy facility in North Carolina

Hurst Boiler | October 27, 2020

Hurst Boiler | August 4, 2020

Hurst Boiler | May 7, 2020

La operación y mantención de plantas térmicas incluye una serie de actividades especializadas que conviene dejar a empresas expertas para obtener mayores beneficios.

Hurst Boiler | April 24, 2020

Over the past two weeks, many of the state advocates for wood heating across the country have mobilized to make clear that the BTU Act will be imperative to our industry's recovery.

Hurst Boiler | April 13, 2020

Hurst Boiler is pleased to announce the promotion of Matt Whittington, a 13-year veteran of the Hurst Boiler Sales team to Domestic Package Boiler Sales Manager.

Hurst Boiler | December 16, 2019

Hurst Boiler | December 16, 2019

Hurst Boiler | December 16, 2019

Hurst Boiler | October 29, 2019

North Carolina ranks among the nation’s key poultry production states and much of its poultry waste is used by farmers as fertilizer. Power Resource Group’s $32 million Farmville plant will convert turkey waste into electricity that is sold to the state’s utilities.

Hurst Boiler | October 28, 2019

Hurst Boiler Company (Coolidge, Georgia, USA) is pleased to announce the first ultra low NOx boiler in California to produce packaged steam that consistently and predictably provides for 2 ppm NOx or less.

Hurst Boiler | June 15, 2018

On behalf of Hurst Boiler Co. and it’s +230 employees we would like to congratulate Mr. Bruce Young, Byron Koch and Lou Schaub of A.B. Young Cos. (Hurst reps in Indianapolis) in the very successful venture with Shambaugh & Sons (design / build contractors) for the construction of the largest milk processing facility in North America.

Hurst Boiler | June 15, 2018

Hurst Boiler, AB. Young Co. and Shambaugh & Sons Contractors combine technologies and services to design, build and equip the largest milk processing facility in North America.

Hurst Boiler | June 8, 2018

Hurst Boiler | May 16, 2018

Hurst Boiler | April 18, 2018

Hurst Boiler | April 18, 2018

Hurst Boiler | April 18, 2018

Hurst Boiler | April 18, 2018

Hurst Boiler | January 20, 2018

Hurst Boiler | August 9, 2017

Hurst Boiler | July 26, 2017

Hurst Boiler | July 6, 2017

Hurst Boiler | June 16, 2017

Hurst Boiler | March 1, 2017

Hurst Boiler | January 3, 2017

Hurst Boiler | August 18, 2016

California Dairy operates a number of plants throughout California, many of which use Power Flame burners in combination with Hurst boilers.

Hurst Boiler | August 10, 2016

Hurst Boiler | May 25, 2016

Hurst Boiler and CRG Boiler Systems partnered to deploy a custom steam and heating solution for ExxonMobil’s Sakhalin-1 Project

Hurst Boiler | April 27, 2016

Hurst Boiler | March 4, 2016

Hurst Boiler | March 4, 2016

Hurst Boiler | February 16, 2016

Hurst Boiler | February 16, 2016

Hurst Boiler | February 16, 2016

Hurst Boiler | February 2, 2016

Hurst Boiler | December 23, 2015

Hurst Boiler | December 9, 2015

Hurst Boiler | November 18, 2015

Hurst Boiler | November 13, 2015

Hurst Boiler powers Kentucky based Willett Bourbon Distillery Expansion

Hurst Boiler | October 30, 2015

Hurst Boiler | October 12, 2015

Hurst Boiler | July 14, 2015

Hurst Boiler | February 19, 2015

Hurst Boiler | January 22, 2015

Hurst Boiler announces launch of its updated website with its new integrated CAD solution that simplifies online boiler selection by making it easy to download or import BIM-compatible 2D and 3D CAD/Revit objects directly into design/specification software.

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 21, 2015

Hurst Boiler | January 17, 2015

Hurst Boiler | August 21, 2014

Perseverance was the key for Sullivan County's District Energy biomass project. It was more than worth the wait.

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Hurst Boiler | August 7, 2014

Daily Iowan | August 6, 2014

University of Iowa officials are testing a new renewable energy source they hope could make the campus more green, but environmental advocates on campus say the move might not be enough.

The university's Oakdale Campus — located northwest of Iowa City — will soon start using a $7.3 million biomass boiler that will replace a gas-powered boiler. The new boiler burns woodchips.

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | August 5, 2014

Hurst Boiler | January 20, 2014

Thermo-Master and Stack-Master are two of the latest, patent-pending engineered product advances Hurst will be introducing to the boiler industry and the world at the 2014 AHR EXPO NY.

Hurst Boiler | January 24, 2013

Hurst Boiler & Welding Co. Inc., stepped up production and fulfillment to meet the emergency boiler needs of areas affected by Hurricane Sandy.Representatives were on-call around the clock to receive and quick-ship orders for a variety of boilers and separators.

Hurst Boiler | January 24, 2013

Hurst Boiler is part of an award-winning installation at the University of Iowa's Oakdale Research Park campus in Coralville, Iowa. As an integral part of UI' s Green Energy Initiative, which seeks to have 40 percent of its energy needs met with renewable resources by the end of 2020, the Hurst biomass boiler replaced the campus's natural gas boiler. Because the project was a retrofit, Hurst had to custom design the biomass boiler solution to fit into an existing structure.

Hurst Boiler | January 24, 2013

Hurst Boiler is part of an award-winning installation at the University of Iowa's Oakdale Research Park campus in Coralville, Iowa. As an integral part of UI' s Green Energy Initiative, which seeks to have 40 percent of its energy needs met with renewable resources by the end of 2020, the Hurst biomass boiler replaced the campus's natural gas boiler. Because the project was a retrofit, Hurst had to custom design the biomass boiler solution to fit into an existing structure.

Hurst Boiler | January 12, 2012

Offering integration, reusability, and scalability, the new, high efficiency Integrated Control Systems from Hurst Boiler for remote boiler room monitoring and communications provide advanced supervisory boiler controls for all new and legacy Hurst products.

Hurst Boiler | October 9, 2011

The high cost of heat has been central to years of discussion and planning for the new pilot biomass boiler system now coming to life at the spectacular Southeast Alaska Discovery Center in Ketchikan.

BiomassMagazine.com | September 12, 2011

The EPA Regulatory Relief Act, which would allow additional time for the U.S. EPA to fix the Maximum Achievable Control Technology Rules, was approved Sept. 13 in the House Energy and Power Subcommittee.

Politico.com | June 18, 2011

What's green, grows on trees, creates jobs and supports healthier forests in rural America?

Hurst Boiler | January 26, 2011

FireMaster is a fully automated monitoring and control system integrated throughout the entire package boiler system from it's make-up water consumption to steam-flow and back as condensate return.

Hurst Boiler | October 23, 2010

Agriculture Secretary Tom Vilsack today announced the award of more than $4.2 million in grants to 13 small businesses and community groups developing innovative renewable energy projects and new product development using woody biomass from hazardous fuel reduction projects on National Forest land.

Hurst Boiler | July 4, 2010

33 teams played in the 17th annual CRMF golf tournament and had participation from over 100 of the hospital's vendors and friends as sponsors, contributors and prize donors!

POWER-GEN WORLDWIDE | May 9, 2010

A requirement that new renewable energy projects needed to have begun construction to qualify for cash grants in lieu of tax credits is being revised by the Department of Treasury.

Hurst Boiler | May 2, 2010

Hurst Boiler recently partnered with Hanesbrands' Dos Rios fabric textiles facility in the Dominican Republic, which is their largest energy-consuming facility, and began operating a state-of-the-art biomass system in January 2009.

Hurst Boiler | February 28, 2010

It's readily available, cost effective, carbon neutral and it makes a very good fuel while cutting dependence on fossil fuels," says a leader on helping industrial, commercial and institutional owners find cost-effective ways to generate steam, power, and chilling, with an emphasis on green energy.

Biomass Magazine | February 2, 2010

The biofuels and biomass industries received nothing but good news Feb. 3, with the release of the long-awaited renewable fuels standard (RFS2) final rule, the first report generated by President Barack Obama's Biofuel Interagency Working Group, and the Biomass Crop Assistance Program proposed rule.

Engineered Systems Magazine | July 29, 2009

The government wanted to have one central location in the north that doesn't have to supply parts for 20 different kinds of boilers," said Fauteux. “This is a good move for their budget, because they can supply all the hospitals through one warehouse, because all the motors and drives are the same from place to place. There isn't a heavy budget for spare parts in each hospital.

American Council On Renewable Energy (ACORE) | July 26, 2009

WASHINGTON, DC - U.S. Department of Energy Secretary Steven Chu today announced more than $54 million in funding from the American Recovery and Reinvestment Act to support energy efficiency and renewable energy projects in Nevada, Rhode Island, Vermont, and Wisconsin.

BBI International | March 31, 2009

Obama administration calls for aggressive biomass spending LAKEWOOD, Colorado — The American economy is in the grip of a crisis unparalleled since the Great Depression. As part of the American Recovery and Reinvestment Act of 2009 presented to Congress, President Obama has included $58 billion to be devoted to energy investments in the coming years — of that, at least $800 million would be directed specifically at biomass-driven energy projects.

esmagazine.com | March 8, 2009

Tighter air regulations and and abundance of trees have paired up to fuel the move toward hybrid biomass boilers in these Canadian hospitals. Read about the upgraded systems' differences and the considerations for trading fossil fuels for sawdust, wood chips, and bark.

Hurst Boiler | February 28, 2009

Fuels for Schools was started in Vermont as a statewide initiative to promote and encourage the use of renewable, local natural resources to provide reliable heat for schools. It has since grown into a multistate program, and has recently expanded its scope beyond schools

American Council On Renewable Energy (ACORE) | February 24, 2009

The American Council On Renewable Energy (ACORE) and the renewable energy industries in America are delighted to have a new administration committed to advancing renewable energy with a plan to create new clean energy jobs with a goal to double alternative energy production in the next three years.

Hurst Boiler | February 6, 2009

Seaman Paper Co. is a 61 year old privately held paper plant located in rural Massachusetts. Under the guidance of George Davenport Jones, III, loyal employees keep this historic facility operating 24/7, 365 days per year. Seaman Paper Co. produces lightweight specialty papers including decorative tissue wraps, crepe streamers, foodservice tissues, SatinWrap, and personalized printed papers.

Associated Press | January 15, 2009

ANCHORAGE, Alaska (AP)—Gov. Sarah Palin has crossed swords with conservation groups over petroleum drilling, but she earned nothing but praise Friday after announcing the most ambitious renewable energy goal in the nation.

MachineDesign.com | January 8, 2009

The Savannah River National Lab, Aiken, S.C., recently replaced a 1950's era coal-burning steam generating plant with a state-of-the-art facility that will burn biomass, mostly wood from the local logging industry. The original plant was too large, so Savannah managers often had to vent much of the steam, which reduced its efficiency. The new plant has two state-of-the-art HURST 30,000 lb/ hr steam boilers, one burning biomass, and the other fuel oil. The fuel-oil boiler is a standby for maintenance periods and peak demands. The plant cost $10 million to build, but should save $1.5 million annually in reduced operating and maintenance costs, as well as less energy consumption. It also meets new Clean Air and Water Act standards.

Hurst Boiler | December 17, 2008

The latest edition in our biomass boiler series is the Hurst Reciprocating Grate Stoker with automated ash removal.

U.S. Energy Information Administration | December 17, 2008

The Annual Energy Outlook 2009 (AEO2009) reference case released today by the Energy Information Administration presents updated projections for U.S. energy consumption and production through 2030

Grainnet | November 18, 2008

Wayne, PA—The federal investment in ethanol over the past three decades has yielded billions of dollars of economic gain, according to a report released November 17 from economic consulting firm LECG, LLC.

Hurst Boiler | August 8, 2008

Chadron State College (CSC), Chadron, Nebraska, is now in its 14th year of firing its central steam heating plant with wood chip fuel produced by a local supplier. Their experience and knowledge gained over that period has application to the present Fuels for Schools (FFS) situation.

Hurst Boiler | August 8, 2008

A $7.3 million central plant with N+1 redundancy on the chillers, generators and boilers in a small hospital in rural southwest Georgia—a dream?

ScienceDaily | July 27, 2008

University of Georgia researchers have developed a new technology that promises to dramatically increase the yield of ethanol from readily available non-food crops, such as Bermudagrass, switchgrass, Napiergrass—and even yard waste.

Ethanol Magazine | July 24, 2008

Cambridge-based Verenium Corp., a cellulosic ethanol enzyme developer and producer, is collaborating with Tokyo-based Marubeni Corp. to continue the advancement of cellulosic ethanol facilities in Asia.

Herald Tribune | July 23, 2008

After years of false starts, a new industry selling motor fuel made from waste is getting a big push in the United States, with the first commercial sales possible within months.

Biodiesel Magazine | July 22, 2008

Algae biofuels in Hawaii are one step closer to reality with the announcement of the joint development of a commercial-scale microalgae facility on the island of Maui.

Hurst Boiler | April 7, 2008

A tollway ramp and part of U.S. 20 have reopened after authorities freed a semitrailer that backed up and could not make it under the Perryville Road overpass.

Hurst Boiler | March 8, 2007

Hurst Boiler & Welding Co., Inc. has authorized the construction of a major building expansion, a project that will double the current size of their manufacturing facilities and corporate headquarters in Coolidge, Georgia to over 220,000 square feet. With their headquarters firmly established as a well-recognized landmark on the ideally situated GA Hwy 319 property, the goals for expansion are to retain the functional and design strengths of the existing structure while crafting an addition that will meet the manufacturer's staffing, business and manufacturing needs through at least the next decade.

Hurst Boiler | August 30, 2023

Hurst Boiler | August 6, 2014

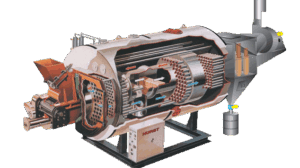

Hurst Boiler, Inc. is the leading manufacturer of gas, oil, wood, coal, solid fuel, solid waste, biomass and hybrid fuel-fired steam and hot water boilers.

Hurst Boiler | August 5, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | January 26, 2022

Hurst Boiler | August 5, 2014

Hurst Boiler | August 6, 2014

Our two-pass, three-pass or four-pass Scotch Marine(Fire Tube) boilers are available in dryback, wetback, steam or hot water versions; from 15 to 800 hp with pressures to 300 psig. Hurst Scotch Marine boilers are rated to 81% minimum efficiency.

Hurst Boiler | August 5, 2014

Hurst Boiler | September 20, 2023

Hurst Boiler | August 10, 2014

We've come a long way since our first shop and we are now housed in a manufacturing facility that encompasses 17 acres, allowing us to manufacture a large variety of boilers to meet the diverse conditions and requirements of customers around the world.

Hurst Boiler | August 6, 2014

Two pass boiler design eliminates refractory baffles between flue gas passes. Minimum maintenance with rugged construction for extra-long life. Efficiencies allow for burning number 5 and number 6 oil with complete combustion with low heat release.

Hurst Boiler | March 24, 2022

Hurst Boiler | July 30, 2015

Clifton Eugene Hurst was above all, a consummate father, husband, and family man. He was also an entrepreneur; he possessed superior engineering skills and he created and ran a successful business built purely on his determination and the sheer force of his inexhaustible will.

Hurst Boiler | August 6, 2014

Two-pass semi wet-back scotch marine boiler. Two pass design eliminates refractory baffles between flue gas passes. Efficiencies are equal to 3 and 4 pass boilers in many cases.

Hurst Boiler | February 21, 2020

Offering integration and scalability, the new, high efficiency Integrated Control Systems from Hurst Boiler for boiler room monitoring and communications provide advanced supervisory boiler controls for all new and legacy Hurst products.

Hurst Boiler | August 6, 2014

HIGH PRESSURE BOILER with capacities from 20 to 2500 BHP. 670 to 83,688 MBTU/HR. Up to 86,250 PPH Steam. 2-pass scotch marine design with wetback construction

Hurst Boiler | August 10, 2014

Hurst Boiler | November 12, 2019

Join us at THE WORLD’S LARGEST HVACR MARKETPLACE.

Learn about industry trends, best practices, and solutions from the people creating them.

The AHR Expo is the world’s largest HVACR event, attracting the most comprehensive gathering of industry professionals from around the globe each year. The Show provides a unique forum where manufacturers of all sizes and specialties, whether a major industry brand or innovative start-up, can come together to share ideas and showcase the future of HVACR technology under one roof. Since 1930, the AHR Expo has remained the industry’s best place for OEMs, engineers, contractors, facility operators, architects, educators and other industry professionals to explore the latest trends and applications and to cultivate mutually beneficial business relationships. The event is co-sponsored by ASHRAE and AHRI, endorsed by many industry leading organizations, and is held concurrently with ASHRAE’s Winter Conference.

Hurst Boiler | August 6, 2014

Three-pass dry back scotch marine boiler. Rear smoke box includes slip-on stack connector and features hinged and davited rear doors.

Hurst Boiler | August 5, 2014

Hurst Boiler | May 3, 2019

Hurst Boiler | August 6, 2014

Three-pass wetback scotch marine boiler uses the latest HVACR technologies and is ideal for all commercial and industrial applications. It provides fuel efficiencies that exceed most four-pass designs. Having no large refractory rear door, these boilers allow one technician easy access to all tubes.

Hurst Boiler | August 19, 2014

Hurst Boiler | May 3, 2019

Hurst Boiler | August 6, 2014

Capacities From 30 to 1500 HP; 1,004 to 50,213 MBTU/HR; 15-300 PSI Steam; Water to 60 PSI 4-PASS SCOTCH MARINE DESIGN with Wetback Construction Low NOx Available, SKID MOUNTED MODULAR PACKAGED

Wetback design eliminates costly deteriorating refractory rear doors and baffles between flue gas passes.

Hurst Boiler | August 19, 2014

Hurst Boiler | August 6, 2014

Modified three-pass scotch marine fire tube boiler. Designed for minimal clearances where installation and floor space are the challenge. Durable features start with the thickest vessel shell in its class, along with large furnace volume for ultimate combustion efficiency.

Hurst Boiler | May 3, 2019

Hurst Boiler | August 6, 2014

LOW PRESSURE BOILER. Modified three-pass scotch marine steam boiler. Designed to fit through a standard 36"x80" door. Durable features start with the thickest vessel shell in its class, along with large furnace volume for ultimate combustion efficiency. Skid Mounted and Modular Packaged.

Hurst Boiler | August 5, 2014

Hurst Boiler | May 3, 2019

Hurst Boiler | August 6, 2014

Three Pass Wet Back Design Scotch Marine Boiler. Extra large furnace for low heat release.

Hurst Boiler | August 19, 2014

Hurst Boiler | May 3, 2019

Hurst Boiler | August 6, 2014

Available in 8 Models from 100 - 2000 BHP. Steam Pressures to 15-300 PSI. Hot Water Section I and Section IV

Hurst Boiler | August 5, 2014

Hurst Boiler | May 3, 2019

Hurst Boiler | August 6, 2014

3 or 4 PASS SCOTCH MARINE DESIGN with Wetback Construction/Combustion. Fuel: Gas or Oil with Combo Electric

Hurst Boiler | August 5, 2014

Hurst Boiler | May 3, 2019

Hurst Boiler | August 6, 2014

Modified two-pass scotch marine boiler. Designed for minimal clearances where installation and floor space are the challenge. Durable features start with the thickest vessel shell in its class, along with large furnace volume for ultimate combustion efficiency.

Hurst Boiler | May 3, 2019

Hurst Boiler | August 11, 2014

Hurst Boiler | August 6, 2014

Hurst's new counter-flow device improves boiler efficiency without increasing the heat transfer surface area and flue gas pressure drop through the boiler.

Hurst Boiler | February 24, 2015

Hurst Boiler is pleased to announce patent approval of the revolutionary new Hurst Boiler Thermal Master Counter-Flow Boiler, engineered with features to improve boiler efficiency.

Hurst Boiler | April 24, 2019

Purpose designed skid packages incorporate Hurst Performance Series boiler(s) with compatible "Factory Matched" auxiliary equipment minimizing over all footprint and shipping expense. In addition there will be a huge time and cost savings during installation phase.

Hurst Boiler | January 22, 2015

HurstBoiler.com now features our new integrated CAD solution that simplifies online boiler selection by making it easy to download or import BIM-compatible 2D and 3D CAD/Revit objects directly into design/specification software.

Hurst Boiler | April 18, 2018

Achieve better efficiencies with a Hurst 500 S 4-PASS SCOTCH MARINE DESIGN with Wetback Construction

Hurst Boiler | August 11, 2015

Take on the annual photo challenge for the new Hurst 2021 Calendar!

Hurst Boiler | August 6, 2014

Hurst Boiler offers premium customized boiler skid packages for all types of steam and hot water boiler applications.

Hurst Boiler | April 18, 2018

Hurst Boiler offers premium customized boiler skid packages for all types of steam and hot water boiler applications.

Hurst Boiler | April 18, 2018

Alternative to Legacy Condensing Boiler Designs Provides Improved Boiler Life

Hurst Boiler | October 1, 2015

Hurst Boiler | April 26, 2018

The innovative design incorporates Hurst-built extra heavy steel boilers and a high-flow heat recovery system that produces the desired boost in efficiency.

Hurst Boiler | January 26, 2017

Hurst Boiler | November 28, 2016

Hurst Boiler | February 16, 2016

Hurst Boiler | August 6, 2014

The Hurst internal stack economizer is a factory-optional device that is designed to increase the operating efficiency of a boiler, cutting down on its operational costs over the lifetime of the boiler.

Hurst Boiler | August 12, 2019

Hurst Boiler | April 8, 2019

Sequenced draft control systems are used to maintain predictable and reliable flue gas pressures at the boiler’s outlet.

Hurst Boiler | February 16, 2016

Hurst Boiler | April 9, 2020

Hurst Boiler has been designated as an Essential Provider and available 24/7 during these difficult times.

Hurst Boiler | February 16, 2016

Hurst Boiler | August 6, 2014

The Hurst Firebox is competitively priced, efficient and flexible three-pass boiler design allowing fuel flexibility for gas, oil, heavy oil, and combination gas/oil.

Hurst Boiler | August 6, 2014

Three Pass Firebox Design. Thickest boiler steel in the industry. Efficient and flexible - gas, oil, heavy oil, and combination gas/oil. Available with Low NOx configuration.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Three Pass Firebox Design. Thickest boiler steel in the industry. Efficient and flexible - gas, oil, heavy oil, and combination gas/oil. Available with Low NOx configuration.

Hurst Boiler | August 6, 2014

Hurst Boiler | January 14, 2023

Hurst Boiler looks forward to another opportunity to express our appreciation for all the wonderful Hurst Boiler sales representatives and associates. Please consider yourself invited to join us for this year’s annual sales awards and representative’s appreciation brunch.

Hurst Boiler | August 6, 2014

Our compact, space saving vertical boilers provide exceptionally high efficiencies, lower fuel costs, and extremely rugged construction.

Hurst Boiler | August 24, 2023

On October 6th Hurst Boiler is celebrating Manufacturing Day (MFG Day), an annual event designed to showcase the modern manufacturing industry and inspire the next generation of creators.

Hurst Boiler | August 6, 2014

The Cyclone Hot Water Boiler provides for exceptionally high efficiencies, lower fuel costs, and extremely rugged construction.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 28, 2023

Hurst Boiler | August 6, 2014

The Cyclone Steam Boiler provides for exceptionally high efficiencies, lower fuel costs, and extremely rugged construction.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Vertical fire-tube design features high efficient X-ID Finned Fire-Tubes. Skid mounted packaged systems install easily. VIX Series offers a smaller foot print than most typical vertical boilers.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

The VHF (Vertical Hand Fired) Hybrid Boiler is the latest advance from Hurst, representing our ongoing development in Solid Fuel Boiler Technology.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Boiler and Burner Technology Engineering for a Cleaner Environment. Hurst developed its first low emission (Low NOx) boiler in 1992, and has been incorporating new technologies to improve upon green boilers ever since.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Complete line of boiler room peripherals. From feedwater systems and blowdown separators to completely integrated control systems.

Hurst Boiler | August 6, 2014

The Hurst Feedmiser Automatic Return System provides storage for water make-up and return condensate from the system loop.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

For all types of steam boilers with pressures to 300 psig. Open vented feedwater systems. Fully piped and wired. Industrial rated. Ready to install 30 to 1,000 gallons. (Larger Sizes on Request).

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Packaged Deaerator systems, 5,000 to 200,000 PPH. Conditions feedwater to 0% CO2 and .005cc/liter of oxygen.

Hurst Boiler | August 6, 2014

Hurst Boiler | January 9, 2019

High temperature water purged from the boiler’s “surface” blow-off system carries valuable heat energy that is normally lost to the drain. A Hurst Boiler Heat Recovery System can reclaim this discarded wasted energy and transfer it to the boiler make-up water to increase of overall efficiency.

Hurst Boiler | July 30, 2022

The Hurst Dual-Tank Oxy-Miser “DOM” series boiler feed system is a spray-type Deaerator and condensate surge tank packaged together as a single unit sharing a common stand and pump header.

Hurst Boiler | February 21, 2021

Hurst Boiler | February 23, 2023

The Hurst Dual-Tank Oxy-Miser “DOM” series boiler feed system is a spray-type Deaerator and condensate surge tank packaged together as a single unit sharing a common stand and pump header. The Hurst DOM DA/ST combo tank is available with emergency cross-over piping which allows the surge tank to act as a temporary boiler feed system, keeping the boiler plant in operation while the DA is out of service.

Hurst Boiler | August 6, 2014

Offering integration and scalability, the new, high efficiency Integrated Control Systems from Hurst Boiler for boiler room monitoring and communications provide advanced supervisory boiler controls for all new and legacy Hurst products. FireMaster, BoilerMaster & BioMaster may also be configured to work with any existing boiler- no matter the manufacturer.

Hurst Boiler | March 14, 2023

If you are an ambitious, energetic person who enjoys a friendly environment filled with challenges and the satisfaction that comes with accomplishment.

HURST is the career employer you've been looking for!

Hurst Boiler | August 6, 2014

Hurst Boiler | April 2, 2023

If you are an ambitious, energetic person who enjoys a friendly environment filled with challenges and the satisfaction that comes with accomplishment.

HURST is the career employer you've been looking for!

Hurst Boiler | August 6, 2014

The Hurst Boiler Company (HBC) Blowdown Separator is designed to take water from the boiler during blowdown and reduce it to atmospheric pressure for disposal.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Fossil fuel costs are at an all time high without any relief in sight, making renewable energy the fuel source of the future.

Hurst Boiler | August 6, 2014

Hurst Boiler and Welding Co., Inc. provides its clients with the support and expertise necessary to design, fabricate and install complete coal fired boiler systems from the fuel storage system thru exhaust gas emission mitigation.

Hurst Boiler | August 6, 2014

Hurst Boiler specializes in the design, engineering and manufacturing of wood fired steam and hot water systems. Hurst Wet Fuel and Dry Fuel Configuration Solid Fuel Fired Boilers are specifically designed to utilize a wide range of standard and alternative fuels such as: Wood, Agricultural Back-up, Gas/Oil, Bark, Chipped Mill Waste, Coal, Construction Debris, Hulls, Swine Fuel, Manure, Paper, Rubber, Sawdust, Shavings, & Sludge.

Hurst Boiler | August 6, 2014

Hurst Boiler produces hybrid or conventional; wood fired steam and hot water boilers for commercial and industrial applications. Our wet or dry fuel boiler configurations can utilize a wide range of liquid, gas or solid fuels.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

FireBox LPD HF new hand fired systems are particularly suited for operations with extremely low labor cost environments.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

The Coalmiser HPD (High Pressure) design is suitable for applications to produce high pressure steam or hot water in ranges from 5,000 - 40,000 lbs/hr (4.8 mm BTU - 39 mm BTU) output from 150 up to 250 PSI.

Hurst Boiler | August 6, 2014

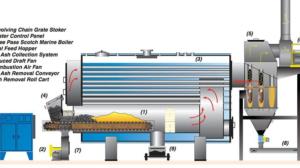

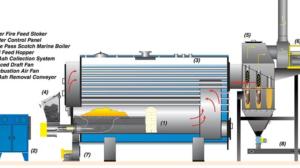

The new HBC reciprocating grate-type stoker system permits biomass fuels with a high proportion of incombustibles to be combusted in an efficient manner with the added advantage of automatic de-ashing.

Hurst Boiler | August 6, 2014

The new HBC chain grate-type stoker system permits a wide range of biomass fuels with high ash contents to be combusted in an efficient manner with the added advantage of automatic de-ashing.

Hurst Boiler | August 6, 2014

HBC's Pneumatic Feed Stoker Systems have proven their ability to provide a very low turn-down rate making it particularly suitable for heating applications in lumber dry kilns, veneer log vats, veneer dryers, greenhouses and factories.

Hurst Boiler | August 6, 2014

With hundreds of these systems in operation, HBC's Under Feed Stoker Systems have proven their ability to provide a very low turn-down rate making it particularly suitable for heating applications in lumber dry kilns, veneer log vats, veneer dryers, greenhouses, and factories.

Hurst Boiler | July 13, 2020

Solid fuel combustion incorporating the simplest replacement of conventional fuels. Our efficient multi-fuel designs in various configurations utilize a wide selection of alternative fuels. Energy solutions based on conventional biomass and engineered biofuels provide clean and renewable energy. Our Biomass, Cogeneration and Solid Fuel Burner Product Line available with Flat Grate, Underfeed and Reciprocating Grate Stokers

Hurst Boiler | July 13, 2020

Solid fuel combustion incorporating the simplest replacement of conventional fuels. Our efficient multi-fuel designs in various configurations utilize a wide selection of alternative fuels. Energy solutions based on conventional biomass and engineered biofuels provide clean and renewable energy. Our Biomass, Cogeneration and Solid Fuel Burner Product Line available with Flat Grate, Underfeed and Reciprocating Grate Stokers

Hurst Boiler | April 6, 2017

Our STAG Series Direct Fired Burners economically and efficiently satisfy your air heating requirements by utilizing readily available waste as a fuel source in lieu of the expensive conventional sources.

Hurst Boiler | February 3, 2015

Our compact, space saving vertical boilers provide exceptionally high efficiencies, lower fuel costs, and extremely rugged construction.

Hurst Boiler | February 3, 2015

Our compact, space saving vertical boilers provide exceptionally high efficiencies, lower fuel costs, and extremely rugged construction.

Hurst Boiler | February 20, 2015

FireMaster is a fully automated monitoring and control system integrated through out the entire package boiler system from it's make-up water consumption to steam-flow and back as condensate return.

Hurst Boiler | February 20, 2015

Advanced design aids in lowering stack temperatures by utilizing make-up feedwater and exhaust gases in a whole new way as a means to increase overall boiler efficiency."

Hurst Boiler | April 18, 2018

The innovative design incorporates Hurst-built extra heavy steel boilers and a high-flow heat recovery system that produces the desired boost in efficiency.

Hurst Boiler | January 14, 2019

Hurst Boiler Engineered Packaged Watertube Boilers

Hurst Boiler | August 6, 2014

GO Carbon Neutral with a Hurst Biomass Boiler System. Reduce Carbon, Reduce Emissions, Reduce Operating and Fuel Costs, and SELL your Carbon Credits.

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 6, 2014

Hurst Boiler | August 11, 2014

Hurst Boiler | August 11, 2014

Hurst Boiler | August 11, 2014

Hurst Boiler | August 11, 2014

Hurst Boiler | August 11, 2014